Electrical work poses no shortage of risks, but the arc flash is arguably one of the biggest dangers. Arc flashes cause or contribute to over 30,000 incidents each year and 400 fatalities. But what’s even more important to understand is that the majority of arc flashes are the direct cause of worker error, and almost every situation can be prevented.

Let’s take a closer look at the dangers of arc flash and what you can do to protect your workers and your company.

What Is an Electrical Arc Flash?

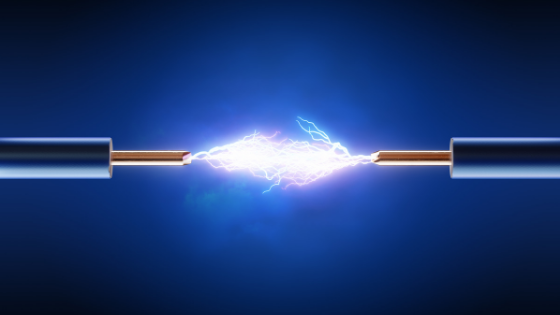

Also called a flash over, an arc flash is the visible part of an arc fault. This occurs when energy is quickly (and unexpectedly) released and travels from one phase Busbar to another, or from a phase Busbar to the ground. The air acts as the conductor for the arc flash as it “jumps” from one source to another. The electrical energy from the arc fault transfers into the surrounding air, transforming into acoustical and thermal energy that can produce a pressure wave and debris. Just how much energy depends on the voltage, amperage, and closure time of the event, but all arc faults have the potential to produce serious consequences.

Arc flashes produce heat and light, often resulting in extremely high temperatures, sometimes up to 35,000 degrees Fahrenheit. Because of its extreme nature, arc flashes can easily result in burns, blasts, fire, flying objects, and heat.

Due to its powerful, unpredictable nature, arc flashes are among some of the most dangerous occurrences on the job. In fact, the National Institute for Occupational Safety and Health (NIOSH) estimate that about five to ten arc flashes occur in the United States every day.

Why Do Arc Flashes Occur?

Arc flashes occur due to one of two things: human error or equipment failure. In most cases, arc flashes occur when work is being performed on equipment or when equipment is operational.

Every case of human error is preventable. The most common error is when workers fail to properly de-energize the equipment prior to working on it. When the distance of two energized sources is decreased, it can allow energy to jump from one to the other, resulting in an arc flash.

Misplacing a tool, a rodent on the loose, and poor insulation can also contribute to arc flashes.

While it’s nearly impossible to predict when an arc flash will occur, you’re not powerless to reduce your risk. Arc flash training can help workers to recognize this invisible danger and know the things that put them most at risk.

What Are the Safety Risks of an Arc Flash?

Workers directly in the path of the arc flash are most at risk, but they aren’t the only ones. When an arc flash occurs, the surge can cause burns to everyone and everything in its path. The shockwave can be powerful enough to knock workers off their feet. If workers are on a ladder or scaffold at the time of impact, it can be enough to knock them off.

Arc flashes may also result in the release of poisonous gases. If a worker inhales the gases, it could lead to lung damage. Electric shocks, vision or hearing issues, sprains, strains, cuts, and fractures are also common consequences. The effects of an arc flash can impact workers who aren’t performing electrical work, too. If an arc flash is powerful enough to start a fire, everyone inside the building is at risk.

How to Protect Your Workers and Company from Arc Flash Effects

Knowing the dangers of an arc flash can be an effective first step in reducing your risk. Ongoing training is critical in helping workers understand and identify potential hazards, as well as ensuring all proper steps are followed when performing any type of electrical work.

De-energizing the circuit can help avoid arc flashes. Train your team to identify and locate all nearby power sources, how to apply lockout/tagout procedures, test for voltage, and ground all power conductors. Taking all the necessary precautions could prevent your company from becoming part of next year’s statistics.

Featured resource: What You Need to Know About Safe Work Permits